Bras in Space: The Incredible True Story Behind Upcoming Film Spacesuit

"We choose to go to the moon. We choose to go to the moon in this decade and do the other things, not because they are easy, but because they are hard, because that goal will serve to organize and measure the best of our energies and skills, because that challenge is one that we are willing to accept, one we are unwilling to postpone, and one which we intend to win, and the others, too." – President John F. Kennedy, September 12, 1962, Rice University.

When we think of the Apollo 11 moon landing, what do we think of? President Kennedy's bold vision. Neil Armstrong and Buzz Aldrin's heroism (unfortunately we rarely think about Command Module Pilot Michael Collins). Perhaps we even think of the incredible engineers, rocket scientists, astrophysicists and all the other geniuses at NASA who made it possible. Now we want you to think about your grandma's bra.

Why? Because without the technology behind that brassiere (or girdle), the moon landing would have been impossible. It turns out that the 21-layers of gossamer-thin fabric in the Apollo spacesuits that kept Armstrong and Aldrin from “the lethal desolation of a lunar vacuum,” as Nicholas de Monchaux puts it in his remarkable book “Spacesuit: Fashioning Apollo,” was created by the same people who made your grandma’s bra. Playtex. And now, Warner Bros. has hired Richard Cordiner to adapt De Monchaux’s book, which is a story so good you almost believe it was scripted by a Hollywood scribe, not part of historical fact.

The creation of the Apollo AL7 Pressure Garment is one of the great American stories of the past forty-plus years. When America pitched itself into the great Space Race, and president Kennedy declared we’d have a man on the moon by the end of the decade, among many of the colossal obstacles NASA had to face was how to make a suit that could withstand space’s incredibly hostile environment. NASA turned the creation of the spacesuit into a competition (largely dominated by military contractors)—and it was assumed a military contractor would win the day.

Instead, pitted against the military-industrial complex, Playtex created the 21-layer spacesuit, each layer distinct yet interrelated in function to the rest of the whole—a masterly combination of elegance, complexity, and form. Where the military contractors created cybernetic, armor-like suits (that failed, and failed again), Playtex's vision was one of crucial softness, world class stitching, and perfect design. Traditional engineering firms could not figure out how to meet all the mission requirements and create a functioning suit that would keep the Apollo astronauts alive. The seamstresses at Playtex, with their years of experience fashioning girdles and bras, could, and did.

We spoke to De Monchaux about this incredible story, the women behind it, and what the Warner Bros. film might look like.

The Credits: How did you dig up this incredible story about Playtex’s involvement?

De Monchaux: It was there in the fact of their authorship in all of the sources I could find. But I actually just became so obsessed with it that I drove to Delaware and just started talking to people, in the company now and then, through them, talking to people who had been around at the time. Unlike most ideas, the more I looked into it the more interesting it became (laughs). I thought, ‘Well this couldn’t really be Playtex, it has to be some totally different division.’ And while it did eventually spin off into a different division, the original Latex that the suits were made of were literally coming from the same tank as the girdle. There were two pipes, and one went over to the girdle assembly line and one went over to the spacesuit assembly line, and I just had this response like, ‘Really?’ I mean that’s so amazing and potentially teaches us so much.

It’s so incredible to think that Playtex entered this competition to design the Apollo spacesuit against all these military firms and won.

Yes. And of course all of the competing suits were designed much more like the missiles and the weapons that the rest of the NASA equipment was adapted from, which is to say designed from their first principles in a very structured way, which works very well when you’re designing that kind of thing, but it turns out it works terribly when you’re designing for the body. The charm of the story is that Playtex, and in particular this kind of obsessive self-taught engineer who was originally a television repair man and Playtex’s founder (Abram Nathaniel Spanel), entered a suit made by his team into the first call that NASA had for Apollo suits. The fact that he thought they could make a suit better than any of these military contractors who’d been making flight suits for years is amazing. But the power of the story is that once that suit was submitted to NASA it was so much better than any of the others that they had to take the firm seriously.

It really does sound like a screenplay for the perfect Hollywood movie, not real life. How did they possibly believe they could compete?

That’s the really interesting part. It’s charming that Playtex thought they could do it and it’s really interesting that they actually did it so much better than anyone else, at least when it came to crafting the suits. They never quite got the hang of the NASA bureaucracy and the paperwork, and that bedeviled them throughout the process and provided the ups and downs of the drama. They were really fired and hired again, and then almost fired again and hired again, so it was never an easy marriage, therefore it was also a really interesting story.

So how did they have any idea how to begin if they designed girdles and bras?

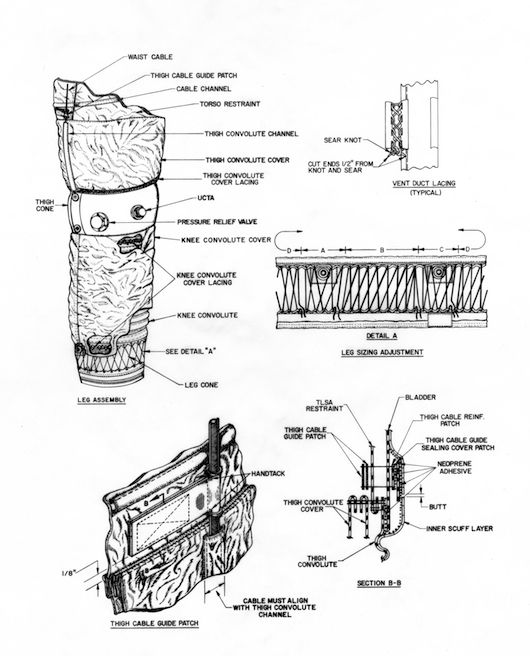

It wasn’t totally unheard of. The Army and Navy had involved corset makers in World War II when they were making the kind of suits that put pressure on the body that helped pilots survive maneuvers, so it wasn’t totally outlandish. But on the other hand, the solution and the actual technology that this guy Len Shepard invented was completely novel, and it was based on a Frankenstein reassembly of all of the ingredients of underwear and bras, the same fabrics and straps and Latex, into this thing called a convolute, which was a special joint material that Playtex invented that allowed its suit to work better than anybody else’s.

So the material that they were using when they were creating their design, that material could withstand the rigors of being out in deep space? Or did NASA use the design and come in with a proper material?

Oh no. It was the same materials. It was bras in space. It was literally the same materials that were used in the bra-making process. The straps from bras were reused to hold the thing into shape and the Nylon fabric that a bra-cup is made of was used to give strength to the Latex so that it didn’t expand under air pressure. Then the Latex itself was the same, as they say it started out as exactly the same Latex as went into the girdles that went into the tank, and then it ended up with a few additives to make it last better and be more flexible over time, but that happened late in the game.

And beyond just the incredible fact that it was a bra and girdle (among other products) company that won this crucial contract, but the people doing the actual work were women.

Yeah, even more important than the material story is the human story, because it was of course made not by men but by women, and the seamstresses who were literally taken off of the bra and girdle line and, instead, asked to create a spacesuit that had to be sewn to within a sixty-fourth of an inch without any pins that might puncture the bladder. So it was kind of a super-human feat of sewing, and on the same regular sewing machines that they used to assemble underwear and undergarments they were sewing 21 layers of fabric together to a sixty-fourth of an inch tall, and, on that seam, the life of the astronauts depended.

It must have been incredible to hear their stories first hand, and, for them, to finally be asked about their contribution to our space program.

They have just the most amazing stories. They’re incredibly proud and they have incredible stories, and no one had really told their story before. That’s what gave me the impetus and energy to get through the book project, to tell their story which is really, really amazing.

How did Playtex figure out how to make airtight zippers and all of these enormously complex things?

They didn't, it was a web of manufacturers. WKK, the zipper manufacturer, figured out the airtight zippers, and part of the reason why that huge bureaucracy was necessary is because this was all a set of moving parts. Somebody else made the backpacks that they were wearing and the bubble helmets were made by a third manufacturer, so they had to integrate themselves into a much larger organizational system.

There are huge differences between the Soviet cosmonaut suit and what Playtex created—can you explain the differences?

Well there are really two differences. One is that Yuri Gagarin’s suit was never designed for someone to really go and do work in. That was the huge new problem that they had in designed the moon suit. Yuri Gagarin’s suit was kind of a safety device, a fall-back, what they call a ‘get me down quick’ suit in case the air supply in his capsule failed. Although, I talk about in the book, it should be known that several Russian cosmonauts actually parachuted to earth in those suits, because they hadn’t worked out the hard landing on the ground yet, so they did have to be sustained by their suit in the upper atmosphere on their way down. But the Russian technological system was even more pragmatic in many ways, and of course it wasn’t a process of competitive bidding, it was a process of just doing whatever would work because the Russian technological complex was in a very different spot than the Americans. They were, on one-hand, much lower-tech, for example instead of a latex bladder they just used a rubber-soaked canvas, and instead of a zipper they just used a tube that you crawled into and then closed with something like a bread clip, but it worked.

Let’s say you were writing the screenplay for Spacesuit. How would you structure your three acts?

The actual story is way crazier and funnier and more absurd [than one you could make up]. It’s already a three-act story, which goes like this; an unexpected supplier initially gets the NASA contract. Then, the supplier loses the contract. Then, they get it back again, but need to master the bureaucracy of NASA and become a real kind of military industrial organization and not just a bra manufacturer. Then the climax of the story is of course the moon landing. I interviewed the guy who represented Playtex in Mission Control, he was the representative for all of the contractors in the upper-viewing gallery during the moon landing. And in my naive way I said to the guy, ‘You must have been so incredibly proud and filled with delight and wonder to see the suit that you and your colleagues made under such arduous circumstances on the moon!’ and he was like ‘Are you crazy? All I was thinking was 'Get them back into the capsule because then it’s not my fault if something goes wrong!’ So it was high stress and high stakes and a lot was riding on what these people found themselves unexpectedly doing.

So Act One, unexpected firm gets the contract, Act Two, they lose it, Act Three they get it back but they have to figure out this byzantine bureaucracy and then the climax, moon landing.

Yes, but I would emphasize to not get me into hot water. That’s not my proposal for the movie, that’s just the way the story is structured in the book. (Laughs).

Featured image: Hazel Fellows assembles the shell, liner and insulation cover of a suit at ILC. Courtesy ILC Dover, LP